According to the Bureau of Labor Statistics there are over 275,000 diesel technician and mechanic jobs in the United States. This includes those that inspect, repair and overhaul trucks, buses or other vehicles that have a diesel engine. These technicians and mechanics may have attended a technical school or learned their trade on the job. The majority have never been trained to work with electric vehicle technology, including how to diagnose, repair or even set up a safe workspace. The EV market, with over 16 million cars, trucks and buses to follow is only growing. Currently, there is a scarcity of training available for these techs to be able to confidently make the transition on behalf of their employers.

The Benefit of Significant History

When it comes to training diesel techs, training departments and internal experts responsible for mentorship have a significant advantage over firms bringing EVs to market. Unlike the EV, the diesel engine has been around for more than 100 years. Over the course of those years OEMs, their customers and stakeholders have amassed a significant experience that resulted in highly refined and effective training material and repair procedures. Generations of techs have had the benefit of being mentored by the master technicians that came before them on equipment that is now very well understood although much more complex than in decades past. Not that a firm would recommend it, but there is a massive amount of training material available on the internet or YouTube that provide how-to instructions including those put out by original equipment manufacturers or even third-party content creators. Any firm looking to create training modules for diesel equipment can leverage content 100 years plus in the making. Unfortunately, these firms do not have the same benefit when developing EV training.

Electric Vehicle Training and Development

Electric vehicles (EV) have been touted to be easier to maintain and have fewer parts for a technicians to be concerned with. However, unlike diesel equipment, there is no prior foundation for the development of EV training content whether they be repair manuals or video how-to instruction. The subject matter experts at OEMs, many of whom are former diesel technicians, are actively creating training content that is being readied for delivery. This is no small exercise. As we may think of technicians as those that diagnose and troubleshoot issues with equipment, EV’s present other challenges for trainers as they must also consider start up and shut down procedures, educating on differences between diesel and EV equipment and safety guidelines which are different and absolutely critical. Another challenge are the technicians themselves.

Technicians Raise Concerns about EV Preparedness

I have had the opportunity to meet with technicians at dealers, independent repair firms, fleets large and small and the next generation, students enrolled in diesel technician programs at technical schools around the country. As we discuss maintenance training , the conversation will inevitably move toward EVs and how the current and future workforce is being prepared for the deployment of this technology. These critical employees have concerns that they will not be prepared for the inevitable adoption of EV training by their employer.

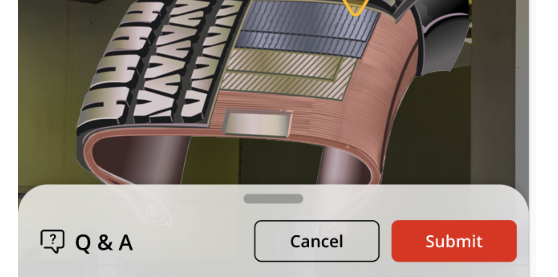

Technician training on augmented reality software.

On a visit to a technical college a soon to graduate diesel technician candidate expressed his concerns that he just spent a significant amount of time learning to maintain equipment that he believes will soon be obsolete. He wondered aloud if there would be a job for him and if the EV equipment is inevitable and coming now. Why he had not received any education on it? Of course, this gentlemen will likely have a long career and maintain diesel equipment but, he felt unprepared and had concern about job prospects as a result.

At a gathering of top technicians from an independent repair firm, a few technicians mentioned apprehension about maintaining the EV equipment. When pressed, their apprehension was directly related to concerns about the safety of working on such equipment. One technician in particular hoped he would just continue to work on diesel and never have to bother with EV training out of fear that it presented an increase in dangerous tasks. Another technician had a concern about switching from diesel to EV throughout the day? These concerns seem borne from information they can read online or discussions among themselves.

Lastly, it seemed clear after speaking with technicians at a fleet that much of the concern has to do with lack of awareness of the differences between diesel and EV equipment. The assumption that much will change leads them to assume they have to relearn what they have learned. The learning would not be restricted to just the power plant either. Technicians at this fleet assumed that many of the parts including brakes would require significant re-learning.

Of course, none of these concerns are insurmountable. The concerns seem to be common to the introduction of any new technology, but the challenge is significant. The adoption of EV technology means training an industry and that is no small task. So how can stakeholders such as OEMs, fleets, dealers, independent repair firms educate the industry?

How XRMentor™ Can Help Train Technicians at Scale for EV Equipment

As EVs deploy, the number of technicians that must be trained among all stakeholders is immense. The cost of this training, particularly if it is done live and in person will be significant and throughput will be a challenge. Any live, hands-on training is most effective if done in small groups of say 6-12. But if you are a fleet with 1000 technicians spread at 25 facilities, it will take an excessive amount of time to train, especially at a level where you can be confident technicians are competent. Now multiple that fleet by others, larger and smaller, then by dealer networks, independent repair contractors and trade schools and consider there are many original equipment manufacturers that will be deploying EVs.

XRMentor™ can reduce the cost of EV training and help improve throughput. It is an easy-to-use instructor-led training and self-guided procedure platform enhanced by augmented reality. It enables firms to rapidly create, deploy and edit how-to instructor not just within their own organization, but for the benefit of others. This makes XRMentor™ well suited to help firms deploy or onboard EV equipment.

- Live Stream Hands-On Demonstrations at Scale. Firms can perform hands-on demonstrations to remote technicians at scale using XRMentor™’s instructor -led training feature ClassroomXR™. Instructors can provide first person perspective and take hundreds the under vehicle, in the cab or under the hood. ClassroomXR™ also gives the instructor the flexibility to share their computer screen or connect easily to an external webcam. Best of all, the instructor can leverage AR content, showing animated or interactive 3d CAD models demonstrating how to access equipment and proper tool usage. This dramatically increases the reach of the instructor, improving training throughput.

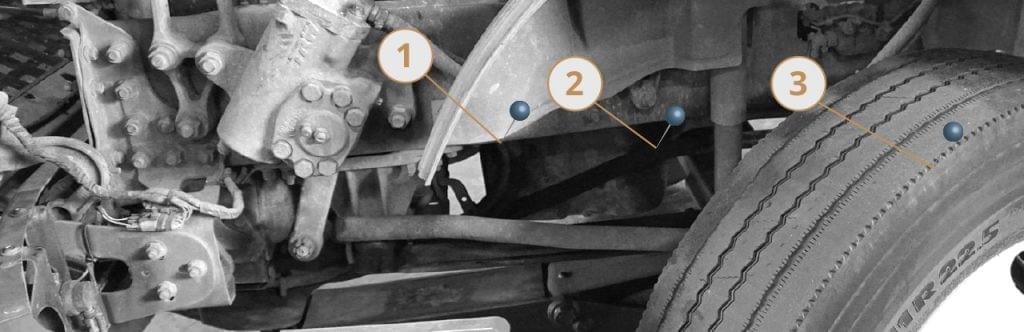

- Rapidly Distribute How-To’s and Videos: XRMentor™ allows instructors to record their hands on demonstrate and create How-To guides. Both of these can be distributed to remote technicians instantly on mobile devices (both iOS and Android) and the Microsoft HoloLens. This makes repair guides available on demand, anywhere, anytime and right at the point of need. Imagine a technician guided step by step through a brand new process on an EV. The likelihood of error is very small, compliance to safety precautions is assured and there is a high probability of getting the job done right the first time.

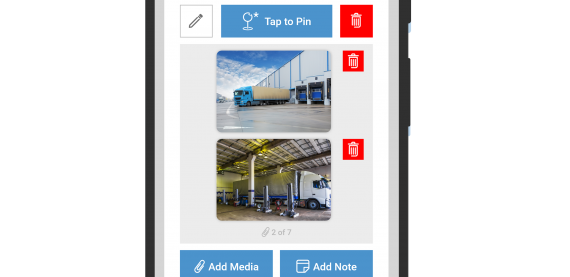

- Create Content in the Field. No doubt a technician will encounter a novel challenge and often these present great training opportunities. Rarely is the instructor in the field when this presents itself. XRMentor™ enables users to capture pictures, videos and even create full procedures from scratch on mobile devices, including those in AR. Once captured, the content is shared to the cloud and can be used in future training sessions. No training opportunity goes un-captured.

- Troubleshoot in Real Time: Troubleshooting is inevitable with new technology. A challenge presents itself and the technician reaches out for support. XRMentor™ allows video sharing between iOS and Android devices as well as Windows computers. It doesn’t matter if the instructor is on their laptop and the tech is on a mobile device they can connect so the instructor can see what the technicians sees.

It is the collaborative nature of the technology that really gives XRMentor™ its true power. Normally content is created and distributed by the OEM, but XRMentor™ allows them to work with their stakeholders and customers to capture, create and share for the greater benefit of all EV customers. The faster good, accurate content can get to market, the better and more confident technicians will be.

To learn more about XRMentor™ you can contact Matt Johnston at ma**************@***************ve.net or visit www.xrmentor.net